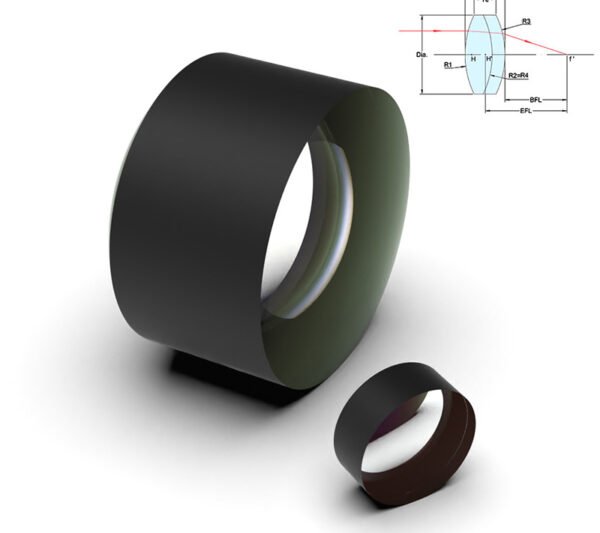

Aluminum non spherical reflector

- Surface finish: 20-10

- Surface type: λ/4

- Effective aperture: 90%

- Dimensional error:+0.0/-0.1mm

- Product manual: The aluminum non spherical reflector is made of AL6061 microcrystalline optical aluminum and processed by a single point ultra precision lathe. Its structure can mainly process free-form surface reflectors, non spherical reflectors, and flat reflectors.

- Category:Ultra smooth glass non spherical surface、metal reflector、glass molded lens、Levicorn spindle、ultra precision optical mold

describe

Aluminum non spherical reflector is a special type of optical reflector, whose surface shape is not a simple sphere, but a free-form surface reflector according to specific optical design requirements. This type of reflector is usually made of aluminum material and undergoes special treatment to achieve excellent optical performance.

General parameters

| Conventional indicators for processing aluminum cylindrical mirrors | |

| material | 6061-T6 |

| Product Category | Aluminum non spherical reflector |

| Processing size (mm) | 10-400 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 60-40 |

| Surface Accuracy | λ/ 10@632.8nm Or higher |

| Optical aperture | >90% |

| reflectivity | <99.5% or higher |

| chamfer | Protective chamfer |

| coating film | Customize according to demand |

characteristic

Non spherical design: The surface of aluminum non spherical mirrors can have complex geometric shapes, which can more effectively focus light, reduce optical distortions (such as spherical aberration, coma, and chromatic aberration), and provide higher imaging quality. The design of non spherical surfaces can optimize optical performance more flexibly and adapt to various application requirements.

Lightweight and Strength: Aluminum is a lightweight and high-strength material commonly used in the manufacturing of optical mirrors, especially in large optical equipment, which can effectively reduce the overall weight and facilitate portability and installation.

Good reflectivity: Aluminum has high reflectivity, especially in the visible and near-infrared spectral ranges. After appropriate coating treatment, the aluminum surface can achieve higher light reflection efficiency and minimize light loss to the greatest extent possible.

application area

- Laser system: Aluminum non spherical mirrors are commonly used in lasers and laser systems to optimize the shape and focusing effect of laser beams.

- Imaging system: Used in microscopes, telescopes, and other imaging devices to improve image resolution and contrast.

- Optical sensors: In smart devices and high-tech sensors, aluminum non spherical mirrors help improve the efficiency and accuracy of light collection, and are widely used in various optical sensing and detection devices.

manufacture

- Manufacturing process: The production of aluminum non spherical reflectors involves precise optical design, CNC machining, grinding, and polishing to ensure that the geometric shape and smoothness of the reflective surface meet high standards. Usually, coating treatment is also required to enhance the reflective performance.

- Processing difficulty: The manufacturing of non spherical shapes is complex and costly, requiring specialized equipment and technology, so special attention must be paid in the design and production process.

Future Development

With the development of optical technology and the emergence of new materials, the design and application of aluminum non spherical mirrors will be enhanced in a wider range of fields, especially in micro nano optics and optoelectronics, providing a lot of innovative potential.

In short, aluminum non spherical reflectors have become an indispensable component in modern optical systems due to their superior optical performance and wide application potential, promoting the development and innovation of optical technology.

If you are interested in our optical components, you can contact us and our engineers will reply to you as soon as possible.

![62a1cd831b01b[1] 62a1cd831b01b[1]](https://asphericoptics.com/wp-content/uploads/2024/09/62a1cd831b01b1-800x701.jpg)