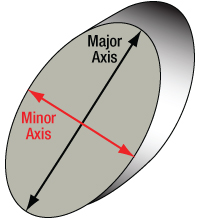

The elliptical mirror has a coating surface on an elliptical ultraviolet fused silica substrate or an elliptical fused silica substrate. When the reflector rotates 45 ° around the short axis of the ellipse, the resulting aperture is circular, as shown in the schematic diagram at the bottom right

Basic principles

The ellipse has two focal points, F1 and F2. According to the geometric properties of ellipses, light rays originating from one focal point (F1) will pass through another focal point (F2) after reflecting off the surface of the ellipse. This property makes elliptical mirrors very useful in accurately transmitting light from one point to another.

application

- optical imaging system:In certain specific optical imaging systems, elliptical mirrors can be used to improve the focusing effect of light, thereby enhancing imaging quality.

- Optical fiber communication:In fiber optic communication systems, elliptical mirrors can be used to accurately guide optical signals from a light source into the fiber optic cable.

- medical equipment:In medical laser equipment, elliptical mirrors can be used to precisely focus the laser onto the treatment area to improve the accuracy and effectiveness of treatment.

- scientific research:In scientific experiments, elliptical mirrors can be used to accurately focus light sources or laser beams onto experimental samples for precise measurement or manipulation.

An elliptical reflector is a special shaped reflector with a surface shape that is a part of an ellipse. This type of reflector has unique applications in the field of optics, especially when it is necessary to transmit light from one point (focal point) to another. Elliptical reflectors utilize the geometric properties of ellipses, where any light reflected from any point on the ellipse will pass through the other focal point of the ellipse.

advantage

- High precision focusing:By utilizing the geometric properties of ellipses, high-precision light focusing can be achieved.

- Flexible light transmission:It is possible to transmit light from one point to another within a larger spatial range without being limited by a straight path.

- Improve optical performance:In specific optical systems, the use of elliptical mirrors can improve the overall optical performance of the system, such as reducing aberrations.

note

- Manufacturing difficulty:Compared to flat or spherical mirrors, the manufacturing of elliptical mirrors is more complex and requires precise machining techniques.

- Strict alignment requirements:The accuracy of aligning the focal point is crucial for achieving the desired optical effect when using an elliptical reflector.

- High cost:Due to the complexity of manufacturing and processing, the cost of elliptical mirrors is usually higher than other types of mirrors.

conclusion

Elliptical reflector is a very useful component in optical design, especially suitable for applications that require precise light transmission and focusing. Despite certain manufacturing and usage challenges, its unique optical properties make it play an irreplaceable role in many high-end optical systems and scientific research.

| Conventional indicators for processing elliptical reflectors | |

| material | Optical glass, optical crystals, etc |

| Product Category | elliptical mirror |

| Processing size (mm) | 10-300 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 60-40 or 10-5 |

| Surface Accuracy | λ/ 10@632.8nm Or higher |

| damage threshold | >5J/cm2,20ns,20Hz,@1064nm |

| Optical aperture | >90% |

| reflectivity | <99.5% or higher |

| chamfer | Protective chamfer |

| coating film | Customize according to demand |

![623f1fdc24a9f-1024x1024[1] 623f1fdc24a9f-1024x1024[1]](https://asphericoptics.com/wp-content/uploads/2024/09/623f1fdc24a9f-1024x10241-1-1024x701.jpg)