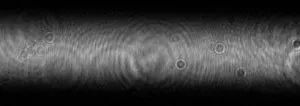

The Powell prism is like a curved roofline of a circular prism. The lens is a laser line generator that stretches a narrow laser beam into a uniformly illuminated straight line.

The Powell prism is a quantum leap line generator with better performance than a simple cylindrical lens. The cylindrical lens produces poor illumination lines, which are limited by non-uniform Gaussian laser beams. The Powell lens’ rounding off the roof is actually the redistribution of spherical aberration along a large number of complex two-dimensional non spherical curves of light; Reduce the light in the central area and increase the light level at the end of the line. The result is the use of very uniform lighting lines in all ways of machine vision applications; From biopharmaceutical and automotive assembly to chocolate biscuit production.

fan angle

The width of the Powell prism sector angle is a function of the refractive index of the glass and roof angles. The steeper the roof and the higher the refractive index, the wider the fan-shaped angle and the longer the time, the line for a given projection distance. Small fan angles typically use mild optical glass with N=1.5 and refractive index. The angle of a large fan should preferably be made of high refractive index glass with N=1.8 or higher to minimize steep angles on the roof

Laser beam size

The size of the incident laser beam determines the thickness of the laser line at a given projection distance. Collimated laser diodes have an elliptical beam profile that allows for thin or thick circuit capability with a single diode module.

An example of narrow incident beam

An example of a wide incident beam

Having a narrow incident beam direction, the long axis of the beam is parallel to the Powell lens roof and generates a thin laser line with a small focusing depth. Having a wide incident beam direction, the long axis of the beam is perpendicular to the Powell prism roof and produces a thick laser line with a large focal depth. The diverging fan in the above figure is cut close to the lens. For each case, the beam is focused onto the CCD array at a working distance of 500 millimeters. The following clear image shows the effect of line width on the shape/direction of the beam.

Narrow incident beam – thin line focal point with narrow depth

Wide incidence beam – thick line focal depth

Narrow incident beam Powell lens optical path

Wide incidence beam Powell lens optical path

The performance and physical characteristics of Powell prisms are driven by the beamwidth. The most significant difference is the foot printing of the divergent fan on the flat exit surface as the installation surface. Care must be taken to ensure that the installation hardware does not trap diverging light.

Uniform lines

The performance of a Powell prism is highly sensitive to the characteristics of the incident laser beam and the quality of the non spherical surface of the lens. For demanding applications, it is best to achieve uniform laser irradiation by matching the specific beam characteristics of the Powell lens to the laser module.

The uniformity of a Powell prism is not an absolute characteristic, it depends on testing techniques. For example, the measure of uniformity will depend on whether an evaluation of the projection line of a Powell prism on a surface seen by a camera or a diverging fan detector of swept light in machine vision applications is used for laser safety assessment. The difference in uniformity characteristics increases the angle of the fan, and the divergence difference of the Powell lens beyond 20 degrees becomes significant.

Optical prisms are used to redirect light at a specified angle. Optical prisms are an ideal choice for light deviation or adjusting image direction. The design of optical prisms determines the interaction between light and light. When light enters an optical prism, it reflects off a single surface or multiple surfaces before leaving, or refracts as it passes through a substrate. Prisms are widely used in laser research, laser optical systems, optical imaging, machine vision, life sciences, biomedicine, and other fields or products.

Calcium fluoride (CaF2) is a commonly used material for manufacturing non spherical lenses. It has high hardness and low refractive index, which can produce thinner lenses.

Calcium fluoride non spherical lenses have high stability and corrosion resistance, making them suitable for use in high temperature and harsh environments. It has good thermal stability and can withstand high operating temperatures, and is commonly used in infrared optical systems.

The surface shape of calcium fluoride non spherical lenses can be elliptical or curved, depending on the requirements of the applied optical system. Its manufacturing technology is relatively complex, usually using techniques such as laser cutting, grinding, or polishing

A Powell prism, also known as a Powell lens, is a specially designed optical element primarily used for laser beam shaping, converting a laser beam into a spot with a specific distribution, such as an approximately uniform straight line or circle. It was invented by American scientist Donald Powell in the second half of the 20th century to address the limitations of traditional optical lenses in laser beam shaping.

application

Powell prisms have a wide range of applications in multiple fields, including:

- laser processing:During laser cutting, welding, and marking processes, Powell prisms are used to shape the laser beam to improve processing efficiency and quality.

- medical equipment:In laser therapy and surgical equipment, the shape of the laser beam is controlled through a Powell prism to achieve precise treatment effects.

- optical detection:In optical measurement and detection systems, Powell prisms are used to generate light spots of specific shapes to improve measurement accuracy and efficiency.

advantage

- Provided an efficient and flexible laser beam shaping method.

- Capable of generating high-quality and uniformly distributed light spots.

- Customized design can be carried out according to specific application requirements.

In summary, the Powell prism is a powerful optical component that can provide precise laser beam shaping solutions in multiple fields. Through its unique design and working principle, the Powell prism can meet the strict requirements for spot quality and distribution in high-end laser applications.

| Conventional indicators for Powell prism processing | |

| material | optical glass |

| Product Category | Powell Lenses |

| Processing size (mm) | 0.25-150 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 60-40 or 20-10 |

| Surface Accuracy | λ/10@632.8nm Or higher |

| angle tolerance | <3′or higher |

| Optical aperture | >80% |

| chamfer | Protective chamfer |

| coating film | Customize according to demand |

![619da6a6419a1-1024x1024[1] 619da6a6419a1-1024x1024[1]](https://asphericoptics.com/wp-content/uploads/2024/09/619da6a6419a1-1024x10241-1-1024x701.jpg)