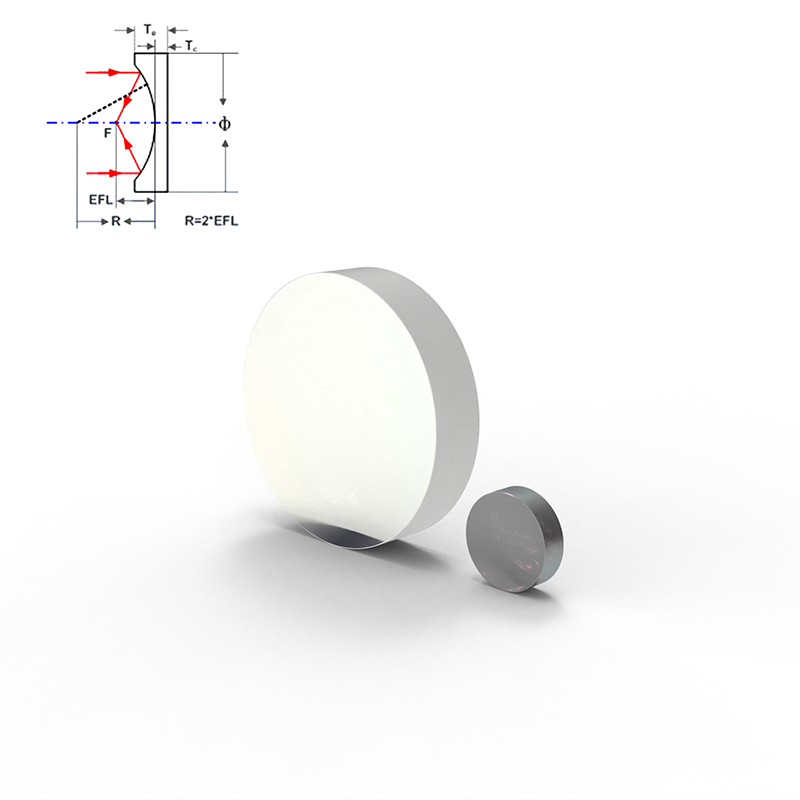

Spherical reflector with optional metal or dielectric coating, with a spectral range from 250 nm to 20 µ m and a focal length from 9.5 mm to 500 mm. Our metal film reflectors include UV enhanced aluminum film (250 to 450 nm), aluminum film with protective layer (450 nm to 2 µ m), silver film with protective layer (450 nm to 2 µ m), gold film with protective layer (800 nm to 20 µ m), and gold film with protective layer for Herriott cell (2 to 12 µ m). The average reflectivity of dielectric film mirrors in the spectral range of 350 to 400 nm, 400 to 750 nm, 750 to 1100 nm, or 1280 to 1600 nm is greater than 99%.

Basic type

Spherical mirrors can be divided into two categories based on their curvature radius and the scattering properties of reflected light:

- concave mirror:The surface of this reflector is concave towards the light source. Concave mirrors can focus parallel incident light at a point called the focal point, so they are commonly used to focus light, such as telescopes, laser focusing systems, etc.

- Convex mirror:The surface of this reflector protrudes outward. A convex mirror diverges parallel incident light rays, making them appear to come from a point behind the mirror (virtual focal point). Convex mirrors are often used to diffuse light or change the direction of light propagation, such as in a vehicle’s rearview mirror.

A spherical reflector is a type of reflector with a spherical surface shape, which is widely used in optical systems to reflect light to change its propagation direction or focus light. The working principle of a spherical reflector is based on the law of light reflection, which states that the angle between the incident light and the reflected light relative to the normal (perpendicular to the reflecting surface) is equal.

application area

Spherical mirrors have a wide range of applications in multiple fields:

- Astronomical telescope:Use large concave spherical mirrors to focus the light emitted by distant stars or other celestial bodies for observation and research.

- LASER SYSTEM:In lasers, concave mirrors are used to focus the laser beam to enhance its intensity and accuracy.

- Lighting:In flashlights or car lights, concave reflectors are used to focus the light emitted by the light source to improve illumination efficiency and range.

- optical instrument:In precision optical instruments such as microscopes and spectrometers, spherical mirrors are used to change the direction or focal length of light propagation to achieve the desired optical effect.

Advantages and Challenges

- advantage:Spherical reflectors are relatively simple to manufacture, have low costs, and can effectively reflect light for focusing or diverging.

- challenge:Spherical reflectors have certain optical defects, such as spherical aberration, which means that light rays from different distances cannot be focused at the same focal point, which can affect the imaging quality. To overcome this issue, high-precision optical applications may choose non spherical mirrors or optimize optical design to reduce the impact of spherical aberration.

conclusion

Spherical reflector is a fundamental and important optical component in the field of optics. Through its simple and effective design, it plays a crucial role in scientific research, industrial applications, and daily life. Despite some optical limitations, these challenges can be effectively addressed through precise design and manufacturing techniques.

| Conventional indicators for processing spherical reflectors | |

| material | Optical glass, optical crystals, etc |

| Product Category | spherical mirror |

| Processing size (mm) | 1-500 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 60-40 or 10-5 |

| Surface Accuracy | λ/ 10@632.8nm Or higher |

| damage threshold | >5J/cm2,20ns,20Hz,@1064nm |

| Optical aperture | >90% |

| reflectivity | <99.5% or higher |

| chamfer | Protective chamfer |

| coating film | Customize according to demand |

![6241b78c564cd[1] 6241b78c564cd[1]](https://asphericoptics.com/wp-content/uploads/2024/09/6241b78c564cd1-800x701.jpg)