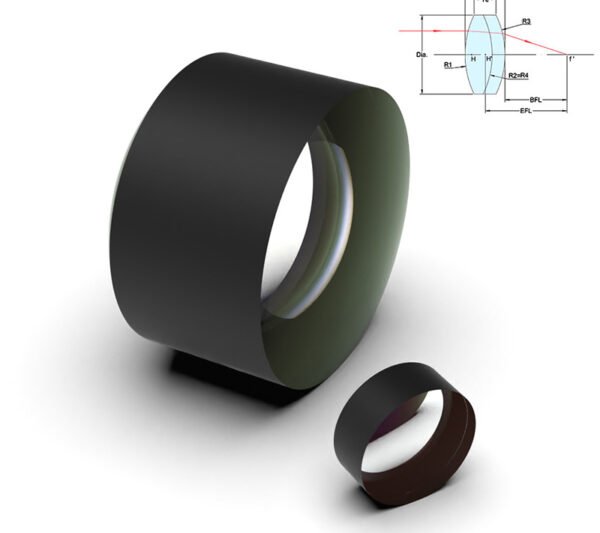

Aluminum cylindrical reflector

- Surface finish: 20-10

- Surface type: λ/4

- Effective aperture: 90%

- Dimensional error:+0.0/-0.1mm

- Product manual: The aluminum cylindrical reflector is made of AL6061 microcrystalline optical aluminum and processed by a single point ultra precision lathe. Its structure can mainly process free-form surface reflectors, non spherical reflectors, and flat reflectors.

- Category:Ultra smooth glass non spherical surface、metal reflector、glass molded lens、Levicorn spindle、ultra precision optical mold

describe

Aluminum cylindrical reflector is a specially designed optical element used to focus or diffuse light in one dimension while maintaining the propagation of light in a direction perpendicular to that dimension. This type of reflector utilizes the shape of a cylindrical surface, where its reflective surface is curved, similar to a portion of the surface of a cylinder. The surface of aluminum cylindrical mirrors is usually coated with an aluminum film to increase reflectivity, especially in the visible and ultraviolet light bands. This type of reflector is very useful in optical experiments, laser systems, spectroscopy, imaging techniques, and other applications that require precise control of the direction of light propagation.

General parameters

| Conventional indicators for processing off-axis parabolic reflectors | |

| Material Science | 6061-T6 |

| Product Category | Off-axis parabolic reflector |

| Processing size (mm) | 10-400 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 60-40 or 10-5 |

| Surface accuracy | λ/ 10@632.8nm Or higher |

| damage threshold | >5J/cm2,20ns,20Hz,@1064nm |

| Optical aperture | >90% |

| reflectivity | <99.5% or higher |

| Chamfering | Protective chamfer |

| Coating | Customize according to demand |

Working principle

The working principle of aluminum cylindrical mirrors is based on the geometric characteristics of their cylindrical shape. When light shines on a cylindrical reflector, due to the curvature of the cylinder, the light will be focused or diffused in the direction perpendicular to the cylinder axis, while the light will not undergo significant changes in the direction parallel to the axis. This enables aluminum cylindrical mirrors to achieve one-dimensional optical operations, such as one-dimensional focusing or diffusion, without affecting the propagation of light beams in another dimension.

manufacturing process

- Shape processing: Firstly, it is necessary to form the precise shape of the cylindrical surface through precision machining techniques such as computer numerical control (CNC) grinding and polishing.

- Aluminum plating: Then, a thin aluminum film is uniformly deposited on the processed cylindrical surface through methods such as physical vapor deposition (PVD) to improve reflectivity.

- Protective film: There may also be a layer of protective film covering the aluminum film to protect it from damage and further improve reflection efficiency and durability.

Aluminum cylindrical reflector is a specially designed optical element used to focus or diffuse light in one dimension while maintaining the propagation of light in a direction perpendicular to that dimension. This type of reflector utilizes the shape of a cylindrical surface, where its reflective surface is curved, similar to a portion of the surface of a cylinder. The surface of aluminum cylindrical mirrors is usually coated with an aluminum film to increase reflectivity, especially in the visible and ultraviolet light bands. This type of reflector is very useful in optical experiments, laser systems, spectroscopy, imaging techniques, and other applications that require precise control of the direction of light propagation.

application area

Aluminum cylindrical mirrors have a wide range of applications in various fields:

- Laser system: used for shape control of laser beams, such as focusing the laser beam into a line or diffusing it in a specific direction.

- Optical experiment: used in physics and optical experiments to control and manipulate the propagation of light.

- Spectroscopy: In a spectrometer, used to focus or disperse light in a spectrum.

- Imaging technology: Used in certain types of imaging systems to improve image quality or achieve specific imaging effects.

advantage

- High reflectivity: Aluminum film provides excellent reflectivity, especially in the visible and ultraviolet light bands.

- Precise control: the ability to accurately focus or diffuse light in one dimension without affecting the propagation of light in another dimension.

- Durability: The combination of aluminum film and protective film provides excellent corrosion resistance and durability, making the reflector suitable for use in various environments.

conclusion

Aluminum cylindrical mirrors are indispensable in many high-precision optical applications due to their unique one-dimensional optical manipulation capability and high performance.

If you are interested in our optical components, you can contact us and our engineers will reply to you as soon as possible.

![167885020661a890f130ffa[1] 167885020661a890f130ffa[1]](https://asphericoptics.com/wp-content/uploads/2024/09/167885020661a890f130ffa1-800x701.jpg)