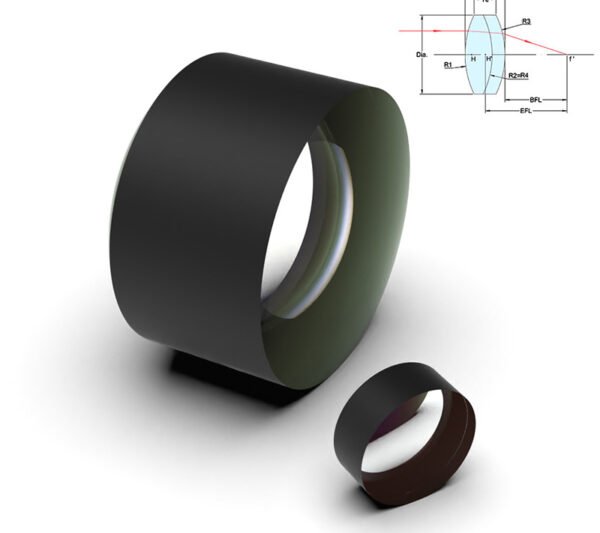

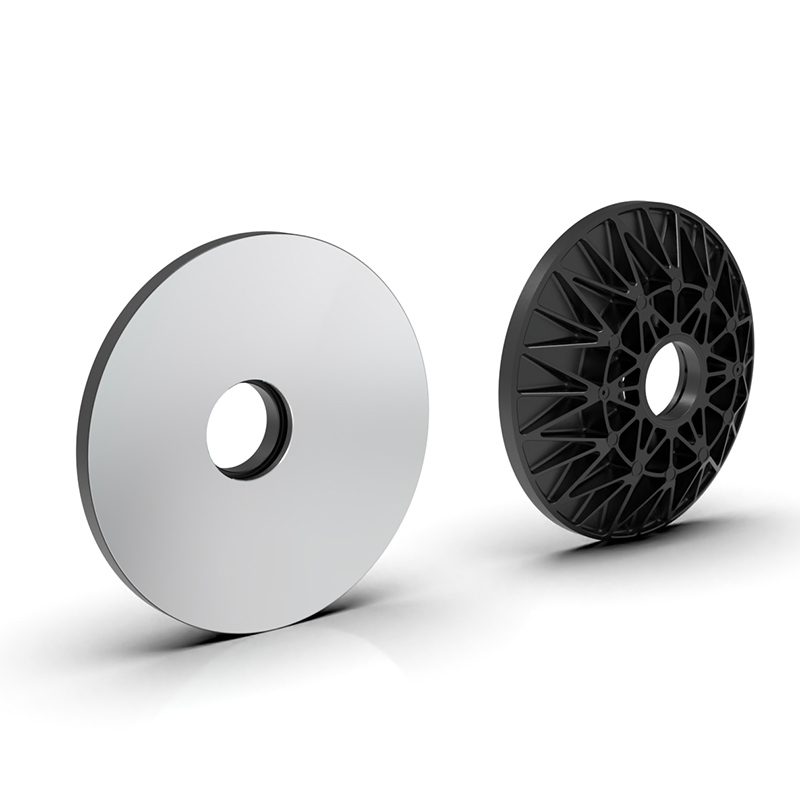

Aluminum Cassegrain system reflector

- Surface finish: 20-10

- Surface type: λ/4

- Effective aperture: 90%

- Dimensional error:+0.0/-0.1mm

- Product manual: The Cassegrain system reflector is made of AL6061 microcrystalline optical aluminum and processed by a single point ultra precision lathe. Its structure can mainly process free-form surface reflectors, non spherical reflectors, and flat reflectors.

- Category:Ultra smooth glass non spherical surface、metal reflector、glass molded lens、Levicorn spindle、ultra precision optical mold

describe

Aluminum Cassegrain system reflector is a specially designed optical reflector commonly used in Cassegrain telescopes, known for their unique optical layout and structure.

General

| Conventional indicators for processing off-axis aluminum cylindrical mirrors | |

| material | 6061-T6 |

| Product Category | Cassegrain system reflector |

| Processing size (mm) | 10-400 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 60-40 |

| Surface Accuracy | λ/ 10@632.8nm Or higher |

| Optical aperture | >90% |

| reflectivity | <99.5% or higher |

| chamfer | Protective chamfer |

| coating film | Customize according to demand |

Characteristics of Aluminum Reflectors

Lightweight: Aluminum materials have the characteristics of lightweight and high strength. Aluminum reflectors can reduce the overall weight in large optical instruments, making them easy to carry and operate.

Good reflectivity: Aluminum has a high reflectivity, especially in the visible light range, and coated aluminum mirrors can achieve high light reflection efficiency, which helps improve imaging quality.

application area

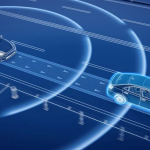

- Astronomical observation: Aluminum Cassegrain system mirrors are widely used in astronomical telescopes, especially large astronomical observation equipment, to collect more starlight and details.

- Optical experiments: In the laboratory, Cassegrain systems can be used for optical testing and research, especially in situations where high-precision imaging is required.

Manufacturing and Challenges

- Manufacturing process: The manufacturing of aluminum reflectors requires high-precision processing techniques, including optical design, aluminum molding, surface treatment, and coating processes, to ensure that the optical performance of the mirror surface meets the requirements.

- Environmental impact: Aluminum materials may be affected by environmental factors, especially in humid or corrosive environments, requiring additional protective measures to ensure the long-term stability and performance of the reflector.

Future Development

With the advancement of technology, the design and manufacturing of aluminum Cassegrain system mirrors are constantly improving to enhance their optical performance, durability, and cost-effectiveness. Their potential in astronomical observations and other applications will become increasingly widespread.

In summary, the aluminum Cassegrain system reflector provides strong support for modern astronomy through its superior optical performance and design flexibility, and has become an important component of high-performance optical equipment.

If you are interested in our optical components, you can contact us and our engineers will reply to you as soon as possible.

![64113a91ecc7f[1] 64113a91ecc7f[1]](https://asphericoptics.com/wp-content/uploads/2024/09/64113a91ecc7f1-800x701.jpg)