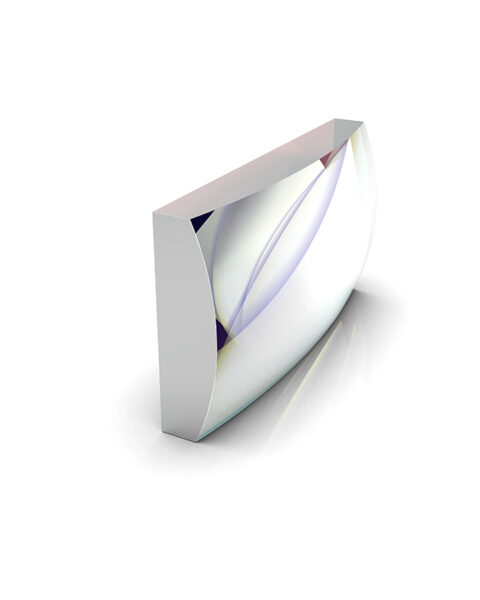

Free-form surface lens

- Product Name: Freeform Surface Lens

- Surface smoothness: 10-5

- Rq:<0.5 nm

- Surface accuracy: λ/40RMS

- Product manual: If you are looking for a manufacturer of freeform lenses, please contact us. We are a professional enterprise that produces high-precision optical components.

- Category:Ultra smooth glass non spherical surface、metal reflector、glass molded lens、Levicorn spindle、ultra precision optical mold

describe

A freeform lens is a type of non spherical lens whose surface is shaped like a freeform surface. The optical performance of free-form surface lenses is superior to spherical lenses, which can improve image distortion and clarity.

Freeform lenses are commonly used in optical systems such as camera lenses, optical instruments, and medical imaging. Its manufacturing technology is relatively complex, usually using techniques such as laser cutting, grinding, or polishing.

The optical performance of free-form surface lenses is related to the material.

General

| Freeform surface lenses can process conventional indicators | |

| material | Quartz Zerodur / Clearceram |

| Product Category | Free-form surface lens |

| Processing diameter (mm) | 50-600 |

| Diameter tolerance (mm) | ±0.03 |

| Surface smoothness (American standard) | 可达10-5 |

| RMS | λ/40 or higher |

| PV | 1/4@632.8nm |

| Optical aperture | >80% |

| core shift | <3 ‘or higher |

| chamfer | 0.2mmX45° |

| coating film | Customize according to demand |

Advantages and Challenges

- Advantages: Freeform lenses have extremely high design flexibility, enabling better optical performance, improved imaging quality, and greater adaptability in spatial conditions.

- Challenge: Due to the complexity of design and manufacturing, the production cost of freeform lenses is usually higher, and the requirements for manufacturing processes and materials are also more stringent.

application

Freeform surface lenses are widely used in high-end optical equipment, laser systems, cameras, microscopes, medical imaging instruments, projectors, and optical sensors. Especially playing an important role in high-tech applications such as biomedical imaging, aerospace, and high-performance optical communication.

manufacturing process

- Advanced processing technology: The process of manufacturing freeform lenses typically involves advanced optical design software, CNC machining, laser processing, grinding, and high-precision polishing techniques to ensure high-quality optical surfaces.

- Surface quality requirements: The optical surface of freeform lenses typically needs to achieve extremely high smoothness and accuracy to ensure optimal optical performance.

Design and Shape

- Complex surface: The surface shape of a free-form lens can be any complex geometric shape, allowing designers to optimize their design based on specific optical requirements and application scenarios.

- High degree of freedom: Compared with traditional spherical and non spherical lenses, free-form surface lenses can provide greater degrees of freedom, making light transmission and focusing more precise.

In summary, free-form surface lenses, with their unique design advantages and excellent optical performance, provide a wide range of possibilities in modern optical applications and drive the development and innovation of optical technology.

If you are interested in our optical components, you can contact us and our engineers will reply to you as soon as possible.

![632a6c37e4a09[1] 632a6c37e4a09[1]](https://asphericoptics.com/wp-content/uploads/2024/09/632a6c37e4a091-800x701.jpg)