Equal thickness off-axis parabolic mirror

- Product Name: Circular Off axis Parabolic Mirror

- Off axis angle: 0-90 degrees

- F/#:F/1 – F/20

- Surface accuracy: λ/40RMS

- Product manual: If you are looking for a manufacturer of off-axis parabolic mirrors, please contact us. We are a professional enterprise that produces high-precision optical components.

- Category:Ultra smooth glass non spherical surface、metal reflector、glass molded lens、Levicorn spindle、ultra precision optical mold

describe

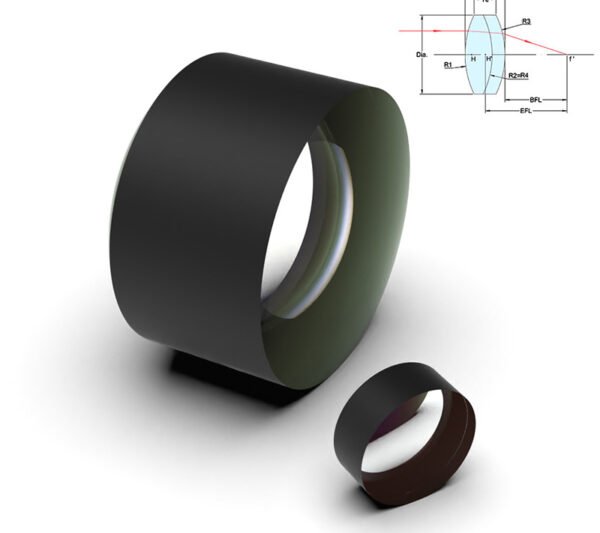

Off axis parabolic mirror is a type of non spherical lens with a parabolic surface shape. The focal position of an off-axis parabolic mirror does not coincide with the incident axis of the light, so it is also known as an off-axis lens.

The optical performance of off-axis parabolic mirrors is superior to spherical lenses, which can improve image distortion and clarity. It is commonly used in optical systems such as camera lenses, optical instruments, and medical imaging.

The manufacturing technology of off-axis parabolic mirrors is relatively complex because their surface shape is not spherical and traditional spherical lens manufacturing methods cannot be used. The manufacturing of off-axis parabolic mirrors usually uses techniques such as laser cutting, grinding, or polishing.

General parameters

| Circular off-axis parabolic mirror can process conventional indicators | |

| material | Fused silica Zerodur / Clearceram、 Monocrystalline silicon and silicon carbide, etc |

| Product Category | Circular off-axis parabolic mirror |

| Processing diameter (mm) | 50-600 |

| Diameter tolerance (mm) | ±0.03 |

| Off axis angle | 0-90 degrees |

| Surface smoothness (American standard) | Up to 10-5 |

| RMS | λ/40 or higher |

| PV | 1/4@632.8nm |

| Optical aperture | >80% |

| core shift | <3 ‘or higher |

| chamfer | 0.2mmX45° |

| coating film | Customize according to demand |

application

- Optical system: widely used in astronomical observation, laser equipment, telescopes, satellite communication, and photography systems. Due to its flexible optical design, it is suitable for a wide range of application needs.

- Imaging technology: In optical instruments for medical imaging, industrial testing, and material analysis, off-axis parabolic mirrors can be used to collect and focus images, improving imaging accuracy.

manufacture

- Precision manufacturing: Manufacturing equidistant off-axis parabolic mirrors requires high-precision machining techniques such as CNC machining, grinding, and polishing to ensure that the optical performance of the mirror surface meets the requirements.

- Design complexity: Due to its off-axis characteristics and equal thickness design, optical engineers need to perform complex calculations to ensure optimal optical performance of the mirror surface.

Future development

With the development of manufacturing technology and optical design software, the design and application of equally thick off-axis parabolic mirrors will become more common, especially in high-speed imaging and high-resolution imaging systems, which have important application prospects.

In summary, due to its superior optical properties and flexible design, equi thickness off-axis parabolic mirrors have become a key component in modern optical applications, demonstrating broad application potential in multiple fields.

If you are interested in our optical components, you can contact us and our engineers will reply to you as soon as possible.

![62ec951ba988c[1] 62ec951ba988c[1]](https://asphericoptics.com/wp-content/uploads/2024/09/62ec951ba988c1-800x701.jpg)